Our Actions | ACER ESG

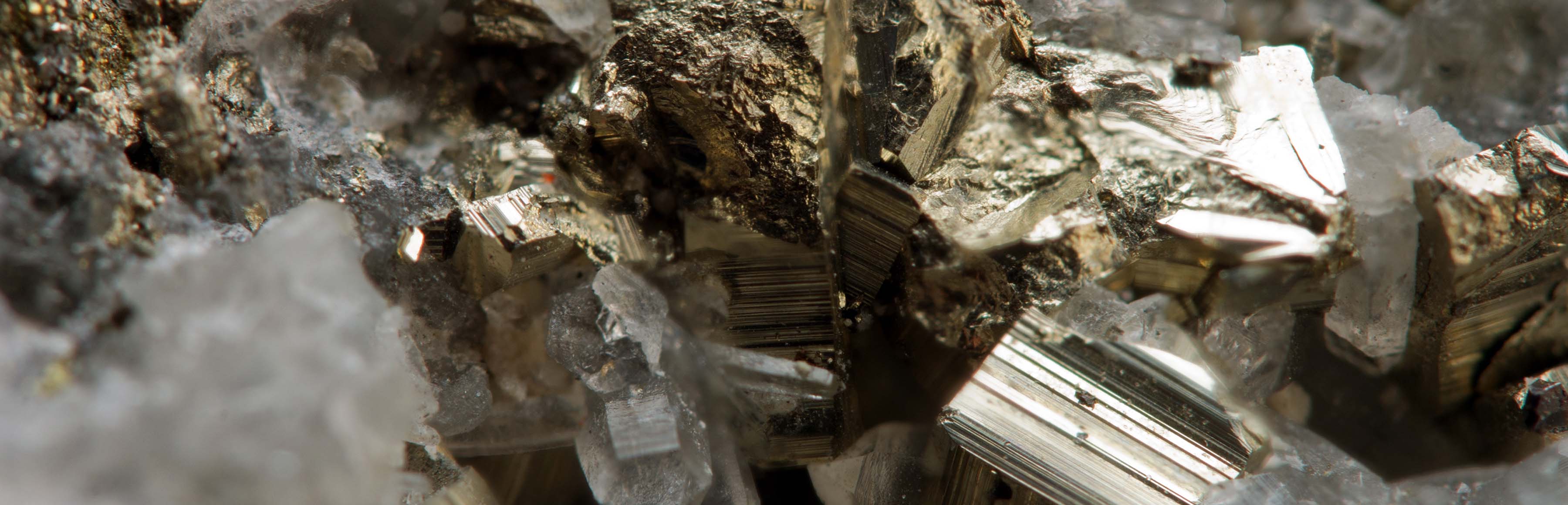

Responsible minerals sourcing continues to be a major focus for Acer. We believe that it is our responsibility to respect the human rights of others and to address adverse human rights impacts that exist where we do business and within our area of influence. As a program that began with a focus on tantalum, tin, tungsten and gold (3TG) in the Democratic Republic of the Congo (DRC), Acer’s Responsible Minerals Sourcing program has expanded to a program capable of addressing any minerals identified by Acer that involve social and environmental risks.

Acer has established Responsible Minerals Due Diligence and Reporting Procedure and Responsible Minerals Risk Management Plan, which are reviewed and updated annually and serve as internal guidelines for the management of responsible mineral sourcing. In 2022, Acer’s responsible minerals sourcing program continued to include 3TG, cobalt, and mica as prioritized minerals in its responsible sourcing strategy. These determinations are based on the prevalence in our products and the sourcing from Conflict-Affected and High-Risk Areas (CAHRAs). Acer will continue to reassess its priority minerals as well as be involved in the refining of the procedures to identify CAHRAs. In 2022, Acer issued its fifth consolidated responsible minerals report, outlining the steps taken to conduct due diligence on all of its priority minerals

2021 Responsible Minerals Report

2In 2022, we completed and published our 2021 Responsible Minerals Report, including a summary of Acer’s responsible minerals supply chain due diligence, future plans, smelter or refiner (SOR) list and mineral country of origin. The report showed progress over the previous year. Acer’s 3TG goal in 2021 was that 98% of SORs shall be conformant to an OECD-aligned 3rd party assessment program and 100% shall be either conformant to or participating in an OECD-aligned 3rd party assessment program. Acer was able to achieve its goal of a 100% conformance or participating rate. However, due to operational status fluctuations in the tin supply chain affecting conformant status, Acer achieved 91% conformant rate, missing its goal of 98% conformant.

For cobalt, Acer saw an increase of identified processors from 21 to 62, 61% of which were either conformant or participating in an OECD-aligned 3rd party assessment program. For mica, it was the first year conducting due diligence and while processes were put in place and supply chain tracing was conducted, the first year resulted in only a few identified processors. It is expected that in the coming years the identified processors for cobalt and mica will increase and Acer will continue with processor outreach to increase participation in the RMAP. To review the results of these activities, please refer to Acer’s most recent 2021 Responsible Minerals Report.

2022 Due Diligence Results

Tantalum, Tin, Tungsten and Gold

As a result of our responsible minerals due diligence measures and the collection of supply chain information for the current 2022 data cycle, we were able to identify 244 unique smelters of 3TG in our supply chain. The quantity of conformant and participating (RMAP-committed) smelters was 244, which is equivalent to 100% of the identified smelters in our supply chain. A summary of our progress year-over-year can be found to the right.

Cobalt and Mica

As part of its responsible minerals program, cobalt and mica are an additional focus for Acer. As a result of its due diligence measures in 2022, Acer was able to identify 62 unique cobalt refiners in our supply chain. The RMAP status improved to 33 RMAP-conformant, 9 participating and 20 that will require outreach. For mica, Acer was able to identify 6 unique mica processors, of which 3 are participating and 3 require outreach.

Other Activities

Acer also continued using the Risk Readiness Assessment (RRA) tool offered through the Responsible Business Alliance (RBA). The tool allows Acer to compare smelters’ and mines’ performance across 32 issue areas covering environmental, social and governance aspects of mining and refining operations, improving our ability to assess and manage risk in our minerals supply chain. At the same time, it allows Acer to engage with suppliers further up the supply chain, which has been a challenge, and also allows the smelter to connect with and have visibility of the downstream companies that use the materials that they place on the market. This helps to emphasize the value of the RMAP certification. At the time of the writing of this report, Acer has received RRAs from 100 processor facilities. The RRA covers the following metals and minerals: Aluminum, Alumina, Bauxite, Cobalt, Copper, Gold, Graphite, Iron Ore, Lead, Lithium, Mica, Molybdenum, Nickel, Palladium, Platinum, Rare Earth Elements, Silver, Steel, Tantalum, Tin, Tungsten, and Zinc.

| 2018 | 2019 | 2020 | 2021 | 2022 | |

|---|---|---|---|---|---|

Conformant | 252 | 235 | 238 | 238 | 227 |

Participating Smelters | 4 | 5 | 11 | 24 | 17 |

Smelters Requiring Outreach | 6 | 2 | 0 | 0 | 0 |

Total | 262 | 242 | 249 | 262 | 244 |

Percentage of Conformant Smelters | 96% | 97% | 96% | 91% | 93% |

Percentage of Conformant or Participating Smelters | 98% | 99% | 100% | 100% | 100% |

Acer continues to follow the OECD Due Diligence Guidance as the basis for its conflict minerals management program and seeks to implement program elements that strengthen Acer’s conformance to those guidelines. We also continue to conduct smelter outreach and communicate smelter details and the results of our efforts to the Responsible Minerals Initiative (RMI) Smelter Engagement Team (SET), as we believe the smelter/refinery identification and disposition are critical components of our due diligence procedure and of maintaining RMAP smelter data. Acer is a member of the SET team and conducts research on global alleged smelters to help determine if they meet the definition of smelters and if they are eligible for the RMAP program.

We continue to hold meetings with suppliers to assess progress on the issue of conflict minerals, to explain Acer’s commitments and supplier requirements, and to ensure they have a thorough understanding of this issue. We will also continue to publish the results of our surveys, and to work with government, industry, and civil-sector groups to resolve supply chain challenges and to support the use of legal, conflict-free minerals.