Acer's Circular Economy Model | ACER ESG

Circular economies differ from the traditional linear economy model in shifting to a cradle-to-cradle circular model that produces no waste. We can accomplish the goals of circular economies through several possible business models, including product sharing, device as a service, repair and refurbishment, remanufacturing, by-products and industrial symbiosis, replacement of raw materials with renewable materials, and resource regeneration and recovery.

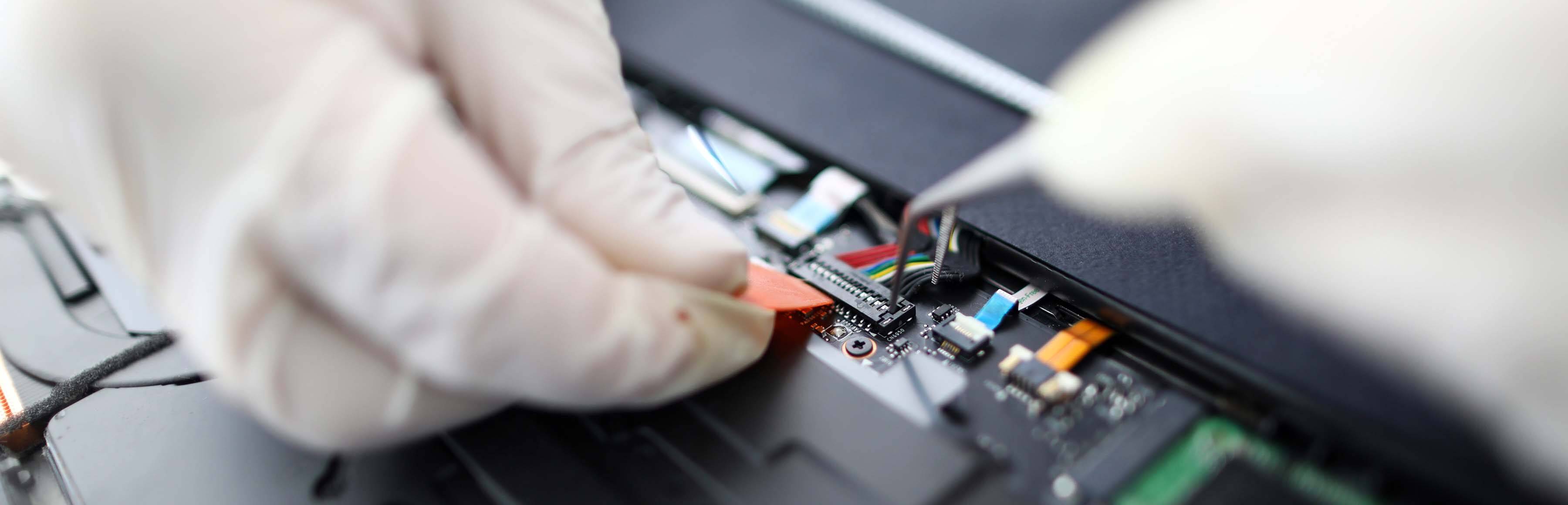

Acer employs the concept of circular economies and strives to reduce the impact of our products on the environment throughout their life cycles. Through product design, we enhance product performance, extend product lifespan, or support resource reuse in product manufacturing.

Product Life Cycle Management

At the product development and design stage, we use low environmental impact materials such as post-consumer recycled plastics for computer and display products. We have also expanded the use of these materials to various products in the Vero series, including projectors and computer peripherals. We also use ocean-bound plastics on our notebook touchpads. In terms of chemical management, we have established banned, restricted, and disclosure substance lists to reduce the use of hazardous substances. In improving product energy efficiency, we base our product design on the US ENERGY STAR standards, while also considering product durability and repairability to extend the product lifecycle.

In the manufacturing process, we work with suppliers to increase efficiency of energy and resources, reduce carbon emissions, and well manage wastes. In terms of process chemicals management, we adhere to the RBA Code of Conduct, requiring suppliers to comply with local regulations, implement effective chemical management systems, and provide workers with appropriate protective equipment and training for workers. Since 2019, we have focused on manufacturing chemicals including toluene, benzene, beryllium dust, chlorinated organic solvents, n-hexane, N-methyl-2-pyrrolidone (NMP), and substances harmful to the ozone layer, and have incorporated this into the annual RBA on-site audits. In 2021, we revised our requirements in accordance with the RBA Industry Focus Process Chemical List (IFPCL). Starting from 2022, suppliers are required to comply with the updated process chemical list, which includes chemicals such as bromopropane, dichloromethane, methanol, tetrachloroethylene, and trichloroethylene. We will continue to monitor industry regulations and evalaute expanding the scope of the concerned process chemical list to reduce risks faced by operators and the environment, also enhance communication and audit in the manufacturing site.. In terms of greenhouse gas and energy management, we require suppliers to response the CDP Supply Chain Climate Change Questionnaire. Furthermore, we will assess suppliers' performance in overall carbon management, carbon reduction achievements, and renewable energy usage through the ESG scorecard. This will help us manage the environmental impact caused by the supply chain. Suppliers' ESG scoring results will be incorporated into procurement evaluations, thereby bolstering the overall supply chain's ability to address climate change. Acer places great importance on the efficient use and reuse of resources during the manufacturing phase. We work closely with our suppliers to enhance resource utilization, reduce energy consumption and greenhouse gas emissions, and implement waste management practices.

During the post-use phase of our products, we offer multiple recycling channels, ultimately ensuring proper recycling and disposal by qualified recycling and processing companies. For more details, please refer to the Product Recycling.

In 2022, we collaborated with our suppliers through the Acer Earthion initiative to minimize environmental impact throughout the design, manufacturing, and transportation stages. Suppliers have installed solar panels and implemented the use of renewable energy to reduce carbon emissions. They have also enhanced their waste management systems, reducing the use of plastic bags in the production line and minimizing the excessive use of security tape when removing containerized pallets, thereby reducing non-recyclable plastic packaging. In addition, the gradual introduction of electric vehicles and biofuel in our product transportation process has also helped us reduce greenhouse gas emissions. For more details, please refer to the Acer Earthion.

Life Cycle Assessment and Product Carbon Footprint

To make a product sustainable, we must examine its impact on the environment and performance at various stages of development, using this as a basis for enhancing the sustainability of future products. As well as emphasizing product life cycle thinking in our green product policy, Acer has also since 2018 introduced a life cycle assessment analysis into the development of IT products across product lines in line with the revised ISO 14001 system. Through this, we gain an insight into the environmental impact of these products. Since 2019, we have also carried out cradle-to-grave full life cycle inventory and assessments for representative products in line with ISO 14040 and ISO 14044 standards. The life cycle assessment results have shown that the two stages with the most significant impact are “raw materials acquisition & component manufacturing” and “product use.” This has led us to set medium-term management goals for product energy efficiency and product raw material use to improve the environmental performance of our products more effectively. In late 2021, the life cycle assessment result of our display product, B247Y, was verified by a third-party to ensure the accuracy and reliability of both the process and the data, providing an important reference for subsequent improvements to product environmental impact. In 2023, the carbon footprint results of our Vero Notebook, AV15-53P, was also verified by a third-party in accordance with ISO 14067:2018 standard.

Since 2021, we completed several full life cycle assessments and product carbon footprints for notebook, desktop and monitors. Please refer to Product Carbon Footprint for details.

Acer’s Circular Economy Model

New business model and Sharing economy

With the new business model of leasing and sharing economy, the services purchasing (rental) is replacing the purchase of hardware equipment such as the DaaS (device as a service) launched by Acer in the pan-European region. DaaS is a complete smart IT solutions with a simplified consumers contract, including hardware, accessories and software solutions for monthly or quarterly payment. Companies using DaaS can rapidly scale their equipment up or down to meet changing demands. Companies can access the latest technology and equipment without having to make large investments. This not only provides the optimal use of resources, but reduces the company's expenditure on IT equipment.

Extend Product Life Cycle

Through product maintenance and refurbishment, the product life cycle is extended as much as possible. For example, HSN, a subsidiary of Acer, provides global support, multi-brand testing, and manufacturer authorized repair and maintenance, from pre-purchase consultation, product function setting, warranty, maintenance, to product recycling at the end of the service life. HSN provides services in every step of the product life cycle, reduce the burden on enterprises and consumers, and improve product performance and reduce environmental impact. Acer’s service center in Taiwan provides quick computer health diagnosis services or computer hardware upgrade promotion during certain periods of time such as the Chinese New Year or the Back to School season where consumers are advised to utilize hardware upgrades to extend product life cycles and reduce electronic waste.

Effective Use of Materials

At the end of the product life cycle, in addition to complying with local regulations for product recycling, Acer has implemented voluntary recycling programs, such as the Acer's Takeback Program in Taiwan. Through 23 service centers and the distribution network across Taiwan, Acer provides regular 3C recycling services for notebooks, mobile phones, tablets, batteries, etc. In addition, Acer actively uses post-consumer recycled plastics and ocean bound plastics in its designs to not only reduce the plastic waste that is difficult to process or may cause environmental pollution when electronic products are discarded,but to promote the development of a circular economy.